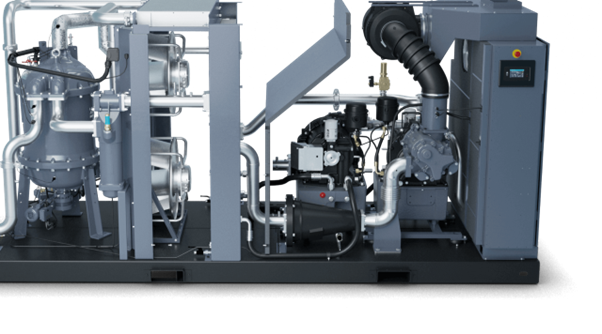

Atlas Copco Oil free screw air compressors ZR & ZT

Atlas Copco Industrial rotary screw oil-free air compressors from 3,5 to 13 bar.

High-efficiency oil-free rotary screw air compressors.

Engineered using innovative in-house technology, the ZR & ZT oil-free air compressors are the result of years of research and development.

Description Atlas Copco ZR/ZT Screw Compressors

Our oil-free rotary screw compressors are designed to achieve low lifecycle costs and deliver high-quality air for industry standards.

ZR & ZT compressors are used in industries that require high compressed air quality standards such as Food & Beverage, pharmaceutical, automotive, medical, textile, power generation, chemical, battery, automotive industries, and many others.

Difference between Atlas Copco ZR & ZT

By selecting either our ZR or ZT compressors, you can have the confidence that your processes and products are protected by clean air, with no contamination originating from the compressor.

The difference? The ZR is water-cooled, and the ZT is air-cooled. With pressure levels ranging from 3.5 up to 13 bar, we maximize your energy savings with our rotary screw technologies with optimal air quality.

All-in-one solution

A compact, all-in-one quality air solution.

ZR and ZT rotary screw oil-free air compressors are available as Full Feature package with:

- integrated dryer for reduced installation space

- variable speed drive (VSD) to minimize your energy costs.

Atlas Copco Technical benefits Screw Compressor

- Certified oil-free air

Class 0 range of compressors, ISO 8573-1 class, you are sure to be working with minimum risk of contamination, unsafe products, or losses from operational downtime. - Energy savings up to 35%

Designed for high efficiency. Save even more energy with our Variable Speed Drive (VSD), our energy recovery feature, and our energy-free MD dryers. - Fast & easy set-up

Plug-and-play packages with integrated dryers, VSD and energy recovery. Easy and low-cost installation and a quick start-up guaranteed. - Optimal reliability

60 years of innovation and experience. Large installed base. Long lifetime through Atlas Copco designed and patented components: stainless steel coolers, AGMA A5/DIN 5 gears and latest Inverter drive systems. Assured quality control by testing every unit. - Global presence – local service

Our aftermarket product portfolio is adapted to your needs. Ensuring optimum availability and reliability of your compressed air equipment at the lowest possible operating costs. - Meets the top quality standard in the food & beverage industry

ISO 22000 certification for our oil-free production facility in Antwerp, Belgium. The food safety management system is applicable to all our Z type class 0 oil-free air compressors and related dryers and filters.

Spesification Standard Oil Free Compressor Atlas Copco:

| Technical Property | Value |

| Capacity FAD l/s | 20 l/s – 2,506 l/s |

| Capacity FAD | 71 m³/h – 9,022 m³/h |

| Working pressure | 3.5 bar(e) – 13 bar(e) |

| Installed motor power | 15 kW – 900 kW |

| Capacity FAD m³/min | 1 m³/min – 150 m³/min |

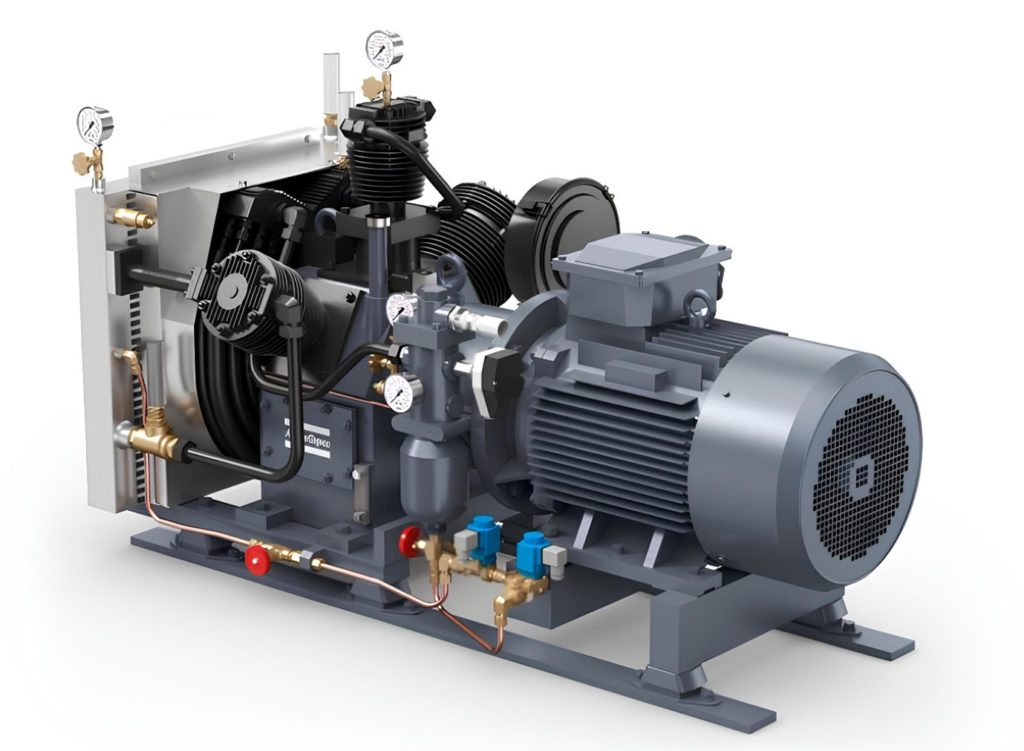

RELATED PRODUCTS

Refrigerant Dryer Tipe FD

Oil Free Scroll Compressor Tipe SF & SF+

Piston Compressor Tipe LT (Medium Pressure)