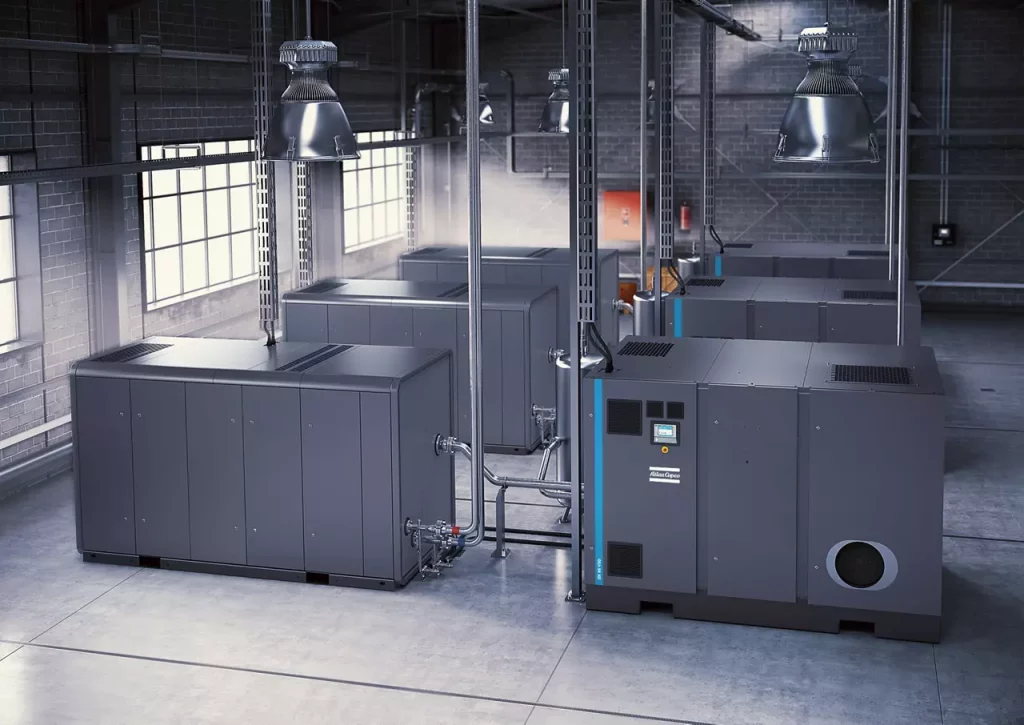

Rotary Screw Air Compressor

Rotary screw compressors are designed for a wide range of users across various industries and applications. They are powered by two counter-rotating screws that compress air as it moves through the compressor.

These units are designed for continuous use, capable of operating 24 hours a day, 7 days a week. They are known for their quiet operation, with noise levels around 60 dBA, and their efficiency in producing compressed air. This type of compressors are more efficient and have a longer lifespan compared to piston compressors, making them a great long-term investment for many industries.

Key Benefits:

- Reliable and Quiet Continuous Operation

- Higher Efficiency

- Longer Lifespan

Industry Solutions:

- Automotive: Enhance your automotive operations with Atlas Copco’s advanced compressed air solutions. Our efficient rotary screw compressors and air treatment systems ensure precision and reliability in every step of vehicle production. Trust our expertise to optimize your processes.

- Food & Beverage: Atlas Copco delivers clean, energy-efficient air solutions tailored to the food and beverage industry. Ensure product safety and quality with our reliable compressors.

- Wastewater Treatment: Atlas Copco provides reliable, energy-efficient air compressors designed for wastewater treatment facilities. Our solutions ensure continuous operation, helping to maintain optimal aeration and other critical processes.

- Chemical & Petrochemical: Atlas Copco offers robust, energy-efficient air compressors tailored for the chemical and petrochemical industries. Our solutions ensure safe, continuous operation in demanding environments, supporting critical processes with reliable compressed air.

- Pharmaceuticals: Atlas Copco provides clean, oil-free air compressors specifically designed for the pharmaceutical industry. Our solutions ensure compliance with stringent hygiene standards, supporting critical processes with reliable, contamination-free air.

- Medical: Atlas Copco offers highly reliable, oil-free air compressors designed for the medical industry. Our solutions ensure a continuous supply of pure, contamination-free air, crucial for patient safety and the operation of sensitive medical equipment.

Variants of Rotary Screw Air Compressors:

- Oil-lubricated Screw Air Compressors

Oil-lubricated compressors inject oil into the compression chamber, which cools and lubricates the compressor element, helps to remove the heat of compression, and minimizes leakage. These compressors are chosen for their continuous operation capability, low oil carryover, and minimal capacity loss over time. They are suitable for a wide range of industrial purposes.

- Oil-Free Screw Air Compressors: Fixed Speed, Dual-Speed or Variable Speed Drive Operation

Oil-free compressors do not use oil in the process, making them ideal for sensitive industrial applications where air purity is critical, such as in the food and beverage or pharmaceutical industries. These compressors still use lubricants for other processes, like motor cooling, but some variants use water as an alternative lubricant. Oil-free types are known for their reliability, efficiency, and ability to deliver the highest air purity at the lowest TCO.

RELATED PRODUCTS

Piston Compressor